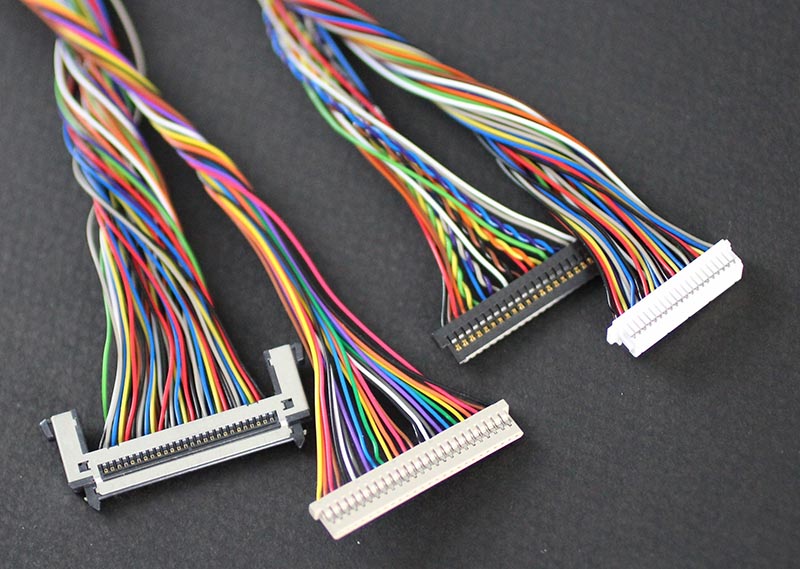

eDP(Embedded display port) and LVDS(Low-Voltage Differential Signaling) are two different display interface technologies, which have significant differences in history, application and technical characteristics.

The historical milieu

-

LVDS:LVDS technology was first proposed by National Semiconductor Corporation (National Semiconductor) in the late 1990 s. As a high-speed, low-power differential signal transmission technology, it is mainly used to solve the signal integrity problem in high-speed data transmission.LVDS technology began to be widely used in industrial control, medical equipment, automotive electronics and other fields around 2000, especially in the display interface.、

-

eDP:eDP is a variant of DisplayPort technology, mainly used for display interfaces in embedded systems. The DisplayPort standard was released by VESA (Video Electronics Standards Association) in 2006, and eDP, as its embedded version, has been mainly applied in mobile devices such as notebook computers and tablet computers since 2010.

Technical characteristics

-

LVDS:LVDS uses low-voltage differential signaling technology with low noise, low power consumption and high anti-interference capability. It usually uses 5V or 3.3V power supply, with small signal swing, suitable for long-distance transmission. The LVDS interface usually includes a pair of differential signal lines (data and clock) for high-speed data transmission.

-

eDP:eDP is based on the DisplayPort standard, uses higher voltages and more complex protocols, and supports higher resolutions and refresh rates. The eDP interface usually uses 1.2V or lower voltage, supports multi-channel data transmission, and is suitable for display requirements with high resolution and high refresh rate.

Field of application

-

LVDS:LVDS is widely used in industrial control, medical equipment, automotive electronics, displays and other fields. Especially in the need for long-distance transmission and low power consumption, LVDS has significant advantages.

-

eDP:eDP is mainly used in notebook computers, tablet computers, all-in-one computers and other consumer electronic products, especially in display devices that require high resolution and high refresh rate, the eDP interface performs well.

Other Information

-

LVDS:LVDS technology needs to pay attention to PCB wiring, differential wire pairs, termination resistance and medium selection when designing to ensure signal integrity and stability.

-

eDP:eDP interface needs to consider the synchronization and timing of signals when designing to ensure the display effect under high resolution and high refresh rate.

To sum up, there are significant differences between LVDS and eDP in terms of technical characteristics, application areas and design requirements. LVDS is more suitable for occasions requiring long-distance transmission and low power consumption, while eDP is more suitable for consumer electronics products with high resolution and high refresh rate.

What is the comparison between LVDS and eDP in the latest technological development?

LVDS (low voltage differential signal) and eDP (enhanced differential video) are two different data transmission technologies, which have their own characteristics and application areas in the latest technological development.

LVDS technology has been widely used in high-speed data transmission systems since the 1990 s. It is a low-voltage differential signaling technology that provides high-speed data transmission capability at low power consumption. According to the evidence, LVDS technology supports data rates ranging from 250 Mbit/s to 1 Gbit/s.In addition, LVDS also has the characteristics of low EMI (electromagnetic interference), which is particularly important for modern high-frequency electronic equipment. In recent years, LVDS technology has been further applied to distributed acquisition systems, radar reconnaissance, high-speed data transmission and other fields, showing its advantages in long-distance and high-speed data transmission.

On the other hand, eDP Technology, although not directly mentioned in the materials I searched, is generally regarded as a standard for display interfaces, especially in laptops and other portable devices. eDP provides an efficient way to transfer data, supporting high-resolution and low-latency display output. Compared with LVDS,eDP is more focused on the transmission of graphics and video data than on general-purpose data communications.

To sum up, the comparison between LVDS and eDP in the latest technological development is mainly reflected in their application fields and technical characteristics. With its high speed, low power consumption and low EMI characteristics, LVDS performs well in a variety of application scenarios that require high-speed data transmission. eDP, on the other hand, is more used in the display field,Especially in devices that require high-quality image and video transmission [[No direct evidence, based on common sense inference]].

What is the maximum resolution and refresh rate supported by the eDP interface?

The maximum resolution supported by the eDP interface can be at least 4K, that is, 3840*2160 pixels. However, the specific value of the refresh rate is not explicitly mentioned in the information I searched. In general, the refresh rate of the eDP interface can range from a few Hz to a few hundred Hz, depending on application requirements and design specifications.

What are the application cases of LVDS technology in modern industrial control and medical equipment?

The application cases of LVDS (low voltage differential signal) technology in modern industrial control and medical equipment mainly include the following aspects:

-

Communication between industrial robot controller and servo drive: In the field of industrial robots, LVDS technology is used to realize high-speed and long-distance data transmission between motion controller and servo drive. This application uses TI's DM3730 and Xilinx FPGA chips, and realizes high-efficiency zero-delay and high-precision data transmission through LVDS technology,The need for high-speed data communication in industrial environments is met.

-

Application of high-speed serial data transmission in industrial control systems: LVDS technology is also widely used in industrial control systems to improve data transmission speed and enhance the anti-interference ability of the field. Compared with the traditional RS232/RS485 bus, LVDS provides faster data transfer rate and better stability.

-

Data transmission between missile-borne data recording equipment and ground test equipment: In the military field, LVDS technology is used for high-speed transmission of large amounts of data between missile-borne data recording equipment and ground test equipment. This application demonstrates the efficiency and reliability of LVDS in handling high-speed long-distance data transmission.

-

Digital optical transceiver design: LVDS technology is also used in the design of digital optical transceiver, used to transmit video, audio and data signals. This design not only improves the stability of signal transmission and lightning protection performance, but also reduces production costs and improves the cost-effectiveness of the product.

-

High-speed signal transmission of imaging photoelectric tracking products: In the field of imaging technology, LVDS technology is used to realize the transmission of long-distance high-speed image data. This application solves the problem of high-speed, large-capacity, long-distance image data transmission, and has good environmental adaptability and electromagnetic compatibility.

-

Image sensor digital system design: in the field of medical imaging, the design of image sensor chip based on LVDS solves the problem of slow data transmission speed of CMOS image sensor. This design effectively improves the data processing capability of the image sensor by converting parallel data into high-speed serial data.