Introduction

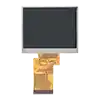

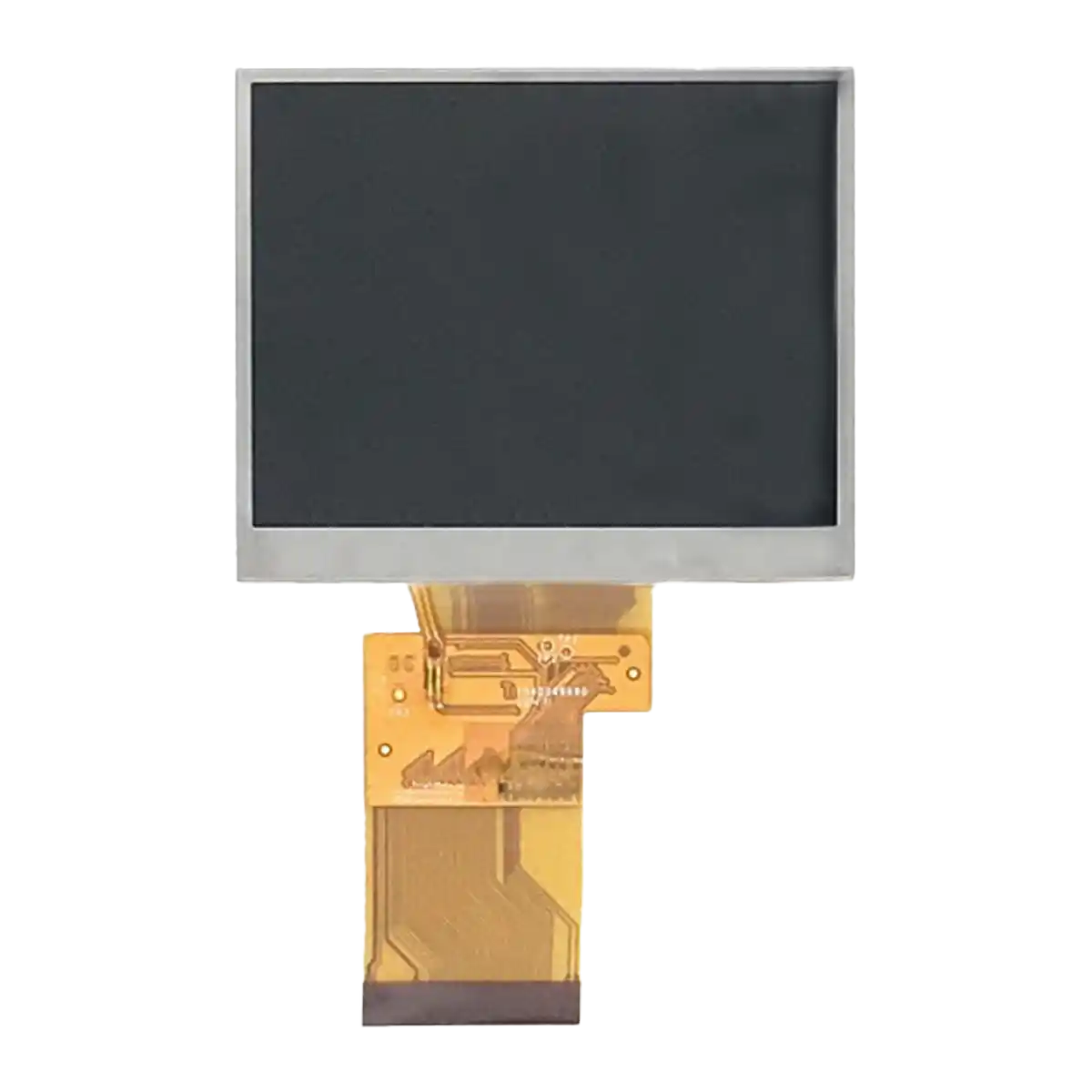

LEEHON provides a screen solution for the control system equipment of oil survey vessels in the marine industry, providing a TCG070WVLQGPNN-AN40 model of KYOCERA as the screen of the control system equipment. This screen is favored for its high brightness, wide temperature and resistance to harsh environments.In this article, we analyze in depth the oil survey vessel control system equipment and show the solution provided by LEEHON. Our solutions are highly adaptable to the equipment of various industries, not only solving the problem of oil survey vessel control system equipment, but also bringing digital solutions to the marine industry.

Text

The control system equipment of oil exploration vessels has undergone a transformation from simple mechanical control to complex electronic and automatic control systems in the course of historical evolution. The central role of these systems is to ensure that the vessel can maintain a stable position and orientation when operating at sea, thereby ensuring the smooth progress of exploration.

Historical evolution of control system equipment for oil survey vessels

-

Early mechanical control: In the early days, oil exploration vessels relied primarily on mechanical devices for basic navigation and positioning. These systems are relatively simple and rely on physical sensors and manual operation to achieve basic ship control.

-

Electronic control systems: With the development of technology, electronic control systems began to be introduced into oil exploration vessels. Such systems include a basic computer control unit and a network of sensors for more accurate navigation and positioning functions.

-

Dynamic positioning system (DP): dynamic positioning system is one of the most critical technologies in modern oil exploration vessels. It enables ships to maintain a specific position and orientation in the ocean by controlling thrusters and other power equipment. This system usually consists of a measurement system, a control system, an electric propulsion system and a rudder device,The control system is responsible for system model calculation, control strategy selection and sensor data fusion.

-

Integrated navigation system: Some advanced oil exploration vessels are also equipped with integrated navigation systems, such as the SPECTRA integrated navigation system, which can uniformly manage the entire navigation control system and improve the reliability and efficiency of the system.

Principle role of control system equipment for oil survey vessels

-

Maintain a stable position: The dynamic positioning system monitors the position and attitude of the ship in real time, and adjusts the working state of the thruster as needed to ensure that the ship can remain in a predetermined position when operating at sea. This is essential for the stability of the drilling platform and the accuracy of the drilling work.

-

Environmental adaptability: Modern dynamic positioning systems also consider the influence of the marine environment, such as wind, waves and currents, and make dynamic adjustments through complex mathematical models and algorithms to cope with various complex marine conditions.

-

Data fusion and Processing: The sensor data fusion technology in the control system can integrate and process data from different sensors to provide more accurate and comprehensive environmental information, thereby optimizing the control strategy.

-

Automation and intelligence: With the development of information technology, more and more intelligent monitoring systems are used in oil exploration vessels. For example, intelligent fuel monitoring systems can improve energy efficiency and reduce human error through remote monitoring and data analysis.

The control system equipment of oil exploration vessels has gradually evolved from the initial mechanical control to a complex electronic and automatic control system. Its core role is to ensure that the vessel can maintain a stable position and direction in the complex and changeable marine environment, so as to ensure the high efficiency and safety of exploration work.

Why must industrial LCD screens be used in the control system equipment of oil survey vessels?

The reasons for the use of industrial LCD screens for oil survey vessel control system equipment can be summarized as follows:

-

High brightness and readability in sunlight: The cockpit of modern ships requires clear display of information in all light conditions. Industrial LCD screens usually have high brightness and can maintain good visibility under direct sunlight.

-

Waterproof and moisture-proof performance: As the ship will be affected by water vapor, sea water and rain when running at sea, the LCD screen needs to have waterproof and moisture-proof characteristics to protect the circuit board and display from moisture and corrosion damage.

-

Impact resistance and high reliability: Industrial LCD screens are designed with impact resistance in mind to ensure stable operation in harsh marine environments. In addition, they also have high reliability and stability, long service life, and do not require frequent maintenance.

-

Multi-angle visibility and optical bonding technology: the industrial LCD screen with IPS panel has an ultra-wide viewing angle (such as 178 degrees), which improves the multi-angle visibility in outdoor situations. At the same time, through optical bonding technology and AG etching surface treatment, the light transmittance is improved and the light reflectivity is reduced, thereby improving the anti-glare effect.

-

Touch screen function and human body induction: Some industrial LCD screens are equipped with touch screen function, which can receive operation instructions through human body induction, which enables users to conveniently perform various controls and settings.

-

Low power consumption and long life: Compared with traditional displays, industrial LCD screens have lower power consumption and no wearing parts and consumables, so the maintenance cost is low, the service life is long, and it is suitable for long-term uninterrupted work.

-

Ability to adapt to complex environments: Industrial LCD screens are specially designed to withstand harsh marine environments and comply with international maritime regulations, making them a reliable and safe choice for maritime operators.

The industrial LCD screen not only meets the basic needs of oil exploration vessels in navigation, monitoring and control, but also provides the advantages of high reliability and long life, ensuring the stable operation of the system and the safety of operation.

Why did the customer choose TCG070WVLQGPNN-AN40 as an industrial LCD screen for the control system equipment of the oil survey vessel?

TCG070WVLQGPNN-AN40 main parameters include:

-

Display resolution: 800 x 480 (WVGA), pixels arranged in RGB vertical stripes.

-

Panel type: a-Si TFT-LCD, LCD module.

-

Brightness: 1000 nits.

-

Operating temperature range:-30 ℃ to 80 ℃, suitable for outdoor applications.

-

Power consumption: Typical value is 4.56W.

-

Signal Type: LVDS(1 channel, 6/8 bit).

-

Life: The backlight life is 70000 hours.

The reasons why customers choose this screen include the following:

-

High brightness and high contrast: The brightness of 1000 nits makes it still visible under direct sunlight, which is very suitable for outdoor environments such as oil exploration ships.

-

Wide temperature operation: The operating temperature range of -30°C to 80°C ensures reliability and stability in extreme weather conditions.

-

Long-life backlight: The backlight life is up to 70000 hours, reducing maintenance costs and replacement frequency.

-

Stable signal transmission: LVDS signal transmission mode is adopted to ensure the stability and reliability of data transmission.

By selecting the TCG070WVLQGPNN-AN40 screen, the customer solved some previous problems, such:

-

Low brightness problem: the previous screen is difficult to see in strong light environment, and the high brightness of the TCG070WVLQGPNN-AN40 solves this problem.

-

Poor temperature adaptability: The previous screen cannot work normally under extreme temperatures, but the TCG070WVLQGPNN-AN40 can operate stably in the range of -30°C to 80°C.

-

Short backlight life: The previous screen backlight life is short and needs to be replaced frequently, while the TCG070WVLQGPNN-AN40 backlight life is as long as 70000 hours, which greatly reduces maintenance costs.

-

Signal instability: The LVDS signal transmission method is used to improve the stability and reliability of the signal and avoid the problem of data loss or error.

Ending

With its high brightness, wide temperature operation, long-life backlight and stable signal transmission, TCG070WVLQGPNN-AN40 has become an ideal choice for customers of oil survey vessel control system equipment. This 7-inch wide temperature, wide viewing angle and high brightness screen are especially suitable for marine industrial environments that need to work under extreme temperatures,Its operating temperature range is -30 ℃ to 80 ℃. The brightness of the screen reaches 1000 cd/m², which can be clearly displayed even in strong light environment, which is very suitable for outdoor or bright industrial environment. In addition, the contrast ratio of the screen is 750:1, and the viewing angle is 85/85/85/85,It ensures a high-quality visual experience from different angles.

LEEHON is committed to innovation and customer satisfaction and understands the importance of continuous improvement. We believe that through our expertise and high-quality solutions, we can bring real value to our customers and move the marine industry forward.