Introduction

Rugged industrial computers, also known as ruggedized or hardened computers, are specifically designed to operate reliably in harsh environments. The history of these devices can be traced back to the early stages of computer technology development. As industrial automation and informatization have advanced, the demand for reliable and durable computers in challenging conditions has increased, giving rise to the concept of ruggedized computers.

The design focus of rugged computers is on enhancing environmental adaptability, high reliability, and maintainability. These computers typically employ specialized system architectures, electrical characteristics, and mechanical-physical structures to ensure normal operation under extreme conditions. For example, they can withstand high temperatures, humidity, strong vibrations, dust, and electromagnetic interference, ensuring stable performance in industrial production settings.

Key Roles of Rugged Displays:

-

Enhanced Physical Durability: Rugged displays are designed with special protective features that improve their resistance to shock, impact, pressure, and temperature, allowing them to function reliably in tough industrial environments.

-

Resistance to Contaminants: In industrial settings, displays are often exposed to dust, oil, and other contaminants. Rugged displays are equipped with protective designs that effectively resist these contaminants, maintaining clear and stable display performance.

-

Adaptability to Complex Environments: Rugged displays can operate in a variety of complex industrial conditions, including high temperatures, humidity, and strong vibrations, ensuring continuous functionality.

-

Improved Real-Time Processing Capabilities: Rugged computers have robust real-time processing capabilities, meeting the demands of industrial automation and informatization, thereby increasing production efficiency and safety.

In summary, rugged industrial displays and computers play a crucial role in modern industry by ensuring stable operation in adverse conditions through specialized protective designs and technical solutions, thus supporting the continuity and efficiency of industrial production.

Historical Development of Rugged Industrial Displays and Computers:

The history of rugged industrial displays and computers can be traced back to the early 20th century, with significant technological advancements and evolutions throughout the 20th century. The evolution of computer hardware, from mechanical calculators to electronic tube computers, then to transistor and integrated circuit computers, and finally to microprocessor-based systems, has paralleled the development of display technologies. Early CRT (Cathode Ray Tube) displays were eventually replaced by LCD (Liquid Crystal Display) technology, which in turn has been supplemented by OLED (Organic Light-Emitting Diode) displays, offering enhanced performance and energy efficiency.

Special Technologies and Materials for Environmental Adaptability:

Rugged industrial displays and computers incorporate various technologies and materials to enhance their environmental adaptability:

-

Material Selection:

-

High-performance VA (Vertical Alignment) liquid crystal materials for wide-temperature operation.

-

Front panels made of aluminum with a brushed finish for aesthetic appeal, mechanical strength, and corrosion resistance.

-

Potting compounds used for sealing and insulation to protect printed circuit boards and LED pins from the environment.

-

-

Thermal Management:

-

High-performance heat sinks, such as graphite sheets, with excellent lateral thermal conductivity to dissipate heat efficiently and reduce temperature differences.

-

-

Mechanical Environmental Adaptability:

-

Anti-vibration and shock-resistant designs, including reinforcement and vibration damping systems, to ensure stability in harsh mechanical environments.

-

Design considerations for low-pressure, low-temperature, high-temperature, humid, and electromagnetic compatibility, validated through environmental adaptability tests.

-

-

Optical Performance:

-

Optical bonding materials to prevent dust and moisture ingress, ensuring screen clarity and environmental adaptability.

-

-

Water and Dust Resistance:

-

Waterproof and fog-proof features to withstand exposure to wind, rain, and sun, prolonging the life of the display.

-

Evaluating Reliability and Durability:

Assessing the reliability and durability of rugged industrial displays and computers involves a combination of methods and techniques:

-

Reliability Testing: Simulating real-world usage scenarios to identify potential issues and validate performance and reliability.

-

Reliability Modeling and Simulation: Using mathematical models and simulations to predict and optimize system reliability.

-

Functional Testing and Quality Control: Comprehensive testing, including functional, brightness uniformity, and temperature tests, to ensure product compliance.

-

Reliability Metrics and Evaluation Methods: Quantifying reliability using statistical, simulation, and experimental methods.

-

Reliability Analysis and Optimization: Applying methods like FMEA (Failure Modes and Effects Analysis) and FTA (Fault Tree Analysis) to identify and mitigate potential failures.

-

Regular Backups and Maintenance: Ensuring regular backups and maintenance to detect and resolve potential issues, reducing the likelihood of system failures.

-

Hardware Failure Analysis: Conducting life tests on components and analyzing failure data to improve overall system reliability.

-

Reliability Assessment Methods: Quantifying system reliability based on specific quantitative metrics and providing a basis for improvement.

Application Cases in Various Industries:

Rugged industrial displays and computers find applications across multiple industries, including:

-

Aerospace and Defense: Widely used in aerospace and defense, where high reliability and durability are critical.

-

Industrial Control: Used in control systems, especially in environments requiring long-term, reliable operation.

-

Transportation: Employed in vehicle, ship, and aircraft systems, ensuring functionality in various environmental conditions.

-

Petrochemicals: Essential in the petrochemical industry, where displays must withstand harsh conditions.

-

Field Operations: Providing stable display performance in rugged outdoor environments.

-

Energy and Power: Utilized in the energy and power sectors, where high reliability and stability are paramount.

-

Semiconductor Manufacturing: Supporting high-tech manufacturing processes with high-performance displays.

-

Railway Transportation: Used in railway systems to ensure reliable operation in diverse conditions.

-

Consumer Electronics: Although primarily used in industrial and military contexts, rugged displays are increasingly being adopted in consumer electronics, particularly in applications requiring high reliability.

Future Trends:

-

Modular Design: Modular design and manufacturing will become an important trend, enabling rapid development of new rugged displays.

-

Adoption of New Technologies: Incorporating new technologies to enhance performance, such as more durable materials, efficient cooling systems, and advanced display technologies.

-

Technology-Driven Transformation: As the industrial landscape evolves, rugged industrial displays will play a key role in this technology-driven transformation, emphasizing intelligence, integration, and ubiquity.

Why G190ETN01.4 and G150XTN06.0 for Rugged Industrial Displays:

-

High Resolution and Color Performance:

-

G190ETN01.4 supports SXGA (1280x1024) resolution with 16.7M colors, ideal for high-precision visual applications.

-

G150XTN06.0 offers XGA (1024x768) resolution with 16.7M colors, providing clear and detailed images.

-

-

Wide Temperature Operation Range:

-

Both models operate in a temperature range of -30°C to 85°C, making them suitable for use in extreme environments.

-

-

High Brightness and Contrast:

-

G150XTN06.0 has a brightness of 450 cd/m² and a contrast ratio of 800:1, ensuring good visibility in various lighting conditions.

-

G190ETN01.4 also provides excellent brightness and contrast, maintaining clear display quality in different environments.

-

-

Long-Life Backlight System:

-

G190ETN01.4 is equipped with a WLED backlight system with a minimum lifespan of 50,000 hours, extending the display's operational life.

-

-

Robust Design:

-

Both displays are rigorously tested to withstand high vibration levels (up to 1.5G) and have good shock resistance, making them suitable for industrial use.

-

-

Multiple Interfaces and Compatibility:

-

G190ETN01.4 uses an LVDS (2-channel, 8-bit) interface, supporting various input signals and ensuring good compatibility.

-

G150XTN06.0 also supports LVDS interfaces and has good signal compatibility, suitable for a wide range of industrial applications.

-

-

Versatile Application Scenarios:

-

These displays are suitable for use in underground, northern, and other harsh weather conditions, ensuring reliable performance in various complex environments.

-

Detailed Specifications:

G190ETN01.4:

-

Size: 19.0 inches

-

Display Technology: a-Si TFT-LCD

-

Resolution: 1280×1024 (SXGA)

-

Brightness: 450 nits

-

Contrast Ratio: 1000:1

-

Color: 16.7M

-

Refresh Rate: 60Hz

-

Backlight System: WLED, lifespan > 50,000 hours

-

Signal Interface: LVDS (2 channel, 8-bit)

-

Operating Temperature Range: -30 ~ 85°C

-

Storage Temperature Range: -30 ~ 85°C

-

Vibration Resistance: 1.5G (14.7 m/s²)

-

Viewing Angle: Wide viewing angle

-

Other Features: No touch screen

-

Size: 15.0 inches

-

Display Technology: a-Si TFT-LCD

-

Resolution: 1024×768 (XGA)

-

Brightness: 450 nits

-

Contrast Ratio: 800:1

-

Color: 262K/16.2M

-

Refresh Rate: 60Hz

-

Backlight System: WLED

-

Signal Interface: LVDS (1 channel, 6/8-bit)

-

Operating Temperature Range: -30 ~ 85°C

-

Storage Temperature Range: -30 ~ 85°C

-

Vibration Resistance: 1.5G (14.7 m/s²)

-

Other Features: No touch screen

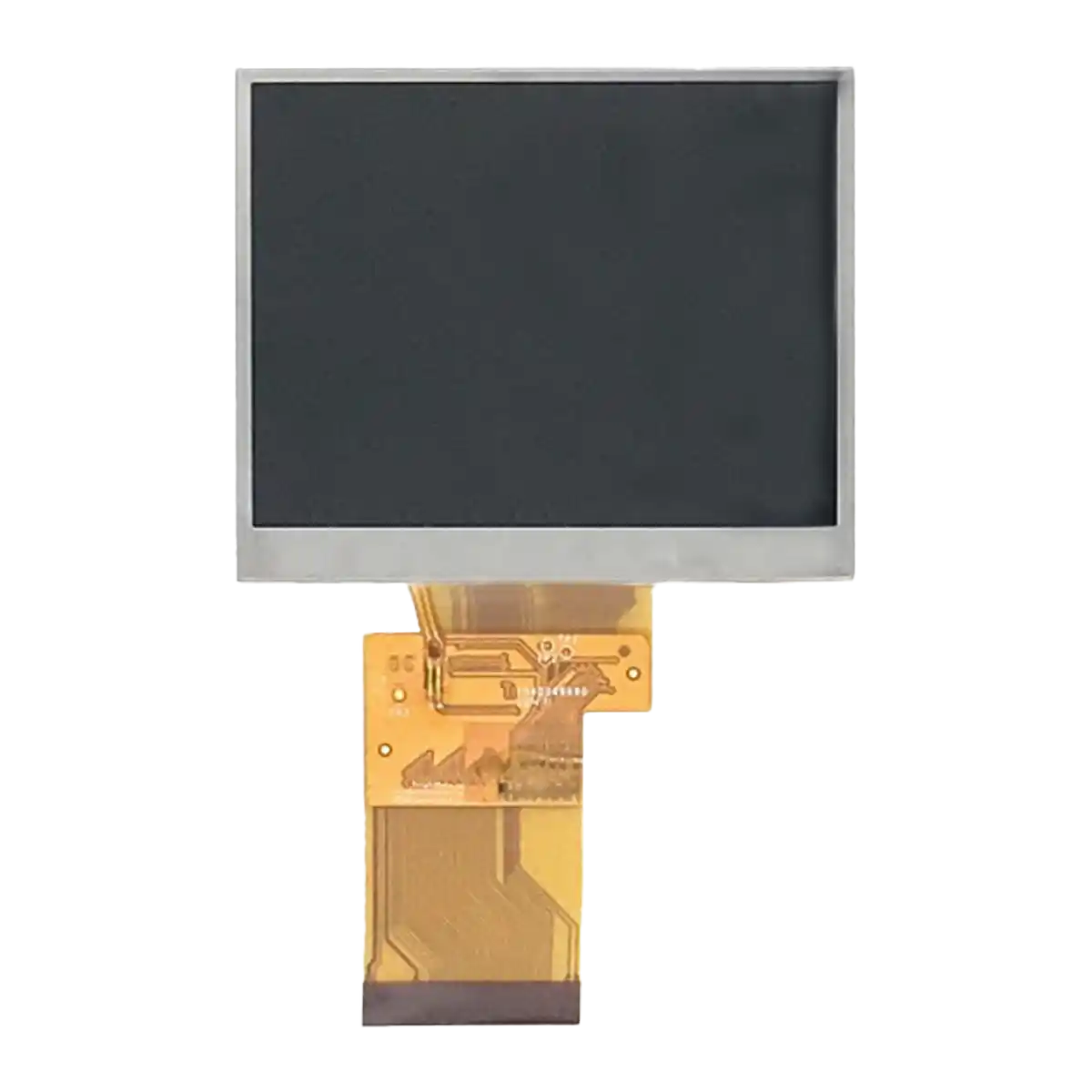

LEEHON’s Solution for Rugged Industrial Displays:

LEEHON provides screen solutions for rugged industrial displays in the industrial sector, offering the G190ETN01.4 and G150XTN06.0 models as screens for these devices. In this article, we have delved into the rugged industrial display and showcased LEEHON's solution. Our solution is highly adaptable to equipment in various industries, addressing the needs for ultra-wide temperature operation (-30 ~ 85°C), stable performance, and reliable supply, while also bringing digital solutions to the industrial sector.

LEEHON is committed to innovation and customer satisfaction. We understand the importance of continuous improvement. We believe that through our expertise and high-quality solutions, we can bring real value to our customers and drive the industrial sector forward.

If you are interested in the above LCD products or need more customized display solutions, please contact our professional team. We are ready to provide you with technical support and consulting services. You can reach us via the following methods:

-

Email: info@leehon.com

Our team is dedicated to serving you, and we look forward to collaborating with you!