Introduction

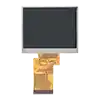

LEEHON provides screen solutions for CNC machine tools in industrial automation, providing BA104S01-300 models of BOE as screens for CNC machine tools. In this article, we analyze the CNC machine tool in depth and show the solution provided by LEEHON. Our solutions are highly adaptable to equipment in various industries,It not only solves the problem of CNC machine tools, but also brings digital solutions to industrial automation. BA104S01-300 are favored for their stable supply and cost-effectiveness.

Text

Historical evolution of CNC Machine tools

The concept of CNC machine tools can be traced back to the early 1940 s, when Parsons, a small aircraft contractor in the United States, used hand-made methods to make plate samples of aircraft wing contours, which were very complicated. Later proposed coordinate boring machine with pulse signal control method, which is the prototype of CNC machine tools.

The world's first CNC machine tool was born in 1952 and was successfully developed by researchers at the Massachusetts Institute of Technology, which marked the initial application of CNC technology. The machine adopts the electronic tube element as the numerical control device, and realizes the three-coordinate continuous control.

Traditional CNC machine stage (1950-1970 s):

During this period, CNC machine tools mainly relied on electronic components such as transistors and printed circuit boards, and CNC systems gradually transitioned from simple mechanical control to electronic control.

Microprocessor applications (1970 s to present):

Since the 1970 s, with the development of microprocessors, Computer technology and servo technology, CNC systems have undergone an evolution from NC(Numerical Control) to NC(Computer Numerical Control). The introduction of microprocessors makes the CNC system more efficient, high-speed and compact.

The working principle of CNC Machine tools

The working principle of CNC machine tools is to realize the precise control of the machine tool through the numerical control device, servo system and detection system, so as to complete the high-precision and high-efficiency processing process.

The numerical control machine tool first carries on the process analysis according to the processed part drawing, writes the processing program, and inputs the processing program into the numerical control device in the digital form. These programs include the shape and size of the part and the process information of the machining process.

After receiving the program, the numerical control system will perform decoding and trajectory interpolation operations. Interpolation operation can solve the problem of irregular shape of parts and ensure machining accuracy.

After decoding the instructions are sent to the servo system, servo system according to the instructions to drive the machine tool parts movement. Each movement is driven by its own motor and electronically coordinated by a computer to achieve a complex feed movement.

The detection system monitors the running state of the machine tool in real time and feeds the data back to the numerical control device. The numerical control device adjusts the processing parameters according to the feedback information to ensure the processing accuracy and stability.

CNC machine tool industry coverage

CNC machine tools are widely used in automotive, aerospace, consumer electronics, engineering machinery, precision molds and other manufacturing industries. It can effectively solve the problem of complex, precise, small batch, and multi-variety parts processing. Its application field is very wide, covering all aspects from simple machining to complex precision manufacturing.

-

Automobile manufacturing: CNC machine tools play a central role in automobile manufacturing, for the production of various parts, such as engines, car bodies, etc.

-

Aerospace industry: In the field of aerospace, CNC machine tools are used to process aircraft wings, fuselage, tail and engine parts, including high-speed five-axis machining centers, gantry mobile high-speed machining centers, etc.

-

Railway locomotive manufacturing: CNC machine tools are also used in the manufacture of railway locomotives to meet specific processing needs.

-

Metal Processing Industry: CNC machine tools are the basic equipment in the metal processing industry, used for cutting, forming and finishing various metal materials.

-

Medical device manufacturing: Due to the high requirements for the accuracy and quality of parts, CNC machine tools are also widely used in medical device manufacturing to meet the needs of rapid delivery.

-

National defense industry, petrochemical industry, power equipment, industrial mold and other fields: CNC machine tools also play an important role in these fields, supporting high-end manufacturing and the production of complex parts.

-

Shipbuilding: CNC machine tools are used to process large structural parts and precision parts in shipbuilding.

-

Power generation equipment manufacturing: In the manufacture of power generation equipment, CNC machine tools are used to process key components, such as turbine blades.

-

Electronic information industry: CNC machine tools are also used in the manufacture of electronic information equipment, especially in the processing of precision electronic components.

-

Emerging areas: With the development of emerging areas such as 5G equipment, new energy vehicles, and smart wearable devices, the CNC machine tool industry will usher in new development opportunities.

By combining with the industrial LCD screen, the above industries can monitor the working status of the machine tool in real time and adjust the parameters in time to optimize the processing process, thereby significantly improving production efficiency.

The industrial LCD screen has the characteristics of high definition, high brightness and high contrast, which makes the operation interface more intuitive and easy to use. For example, the new intelligent CNC machine tool is equipped with a multi-touch panel, which allows users to easily perform operations such as moving, zooming in and out of 3D models and viewing tool data and program information by touching the screen.This intuitive operation not only improves work efficiency, but also reduces the possibility of operation errors.

With the development of Internet of Things (IoT) technology, the combination of CNC machine tools and industrial LCD screens has further promoted the realization of intelligent manufacturing. Through real-time data collection and analysis, operators can remotely monitor the status and production progress of the machine tool, find and solve potential problems in time, and ensure the continuity and stability of production.In addition, the industrial LCD screen can also provide customized display layout to meet the needs of different operators and further improve the overall management level.

Industrial LCD screens usually have the characteristics of waterproof, dustproof, anti-electromagnetic interference, etc., and can operate stably in harsh industrial environments. This is essential for the long-term stable operation of CNC machine tools, because these devices often need to work in high temperature, high humidity or corrosive gas environment.

The main reason for the combination of CNC machine tools and industrial LCD screens is to improve production efficiency, enhance operating experience, realize intelligent management and improve environmental adaptability. This combination not only improves the performance of CNC machine tools, but also promotes the development of the entire manufacturing industry in the direction of digitalization and intelligence.

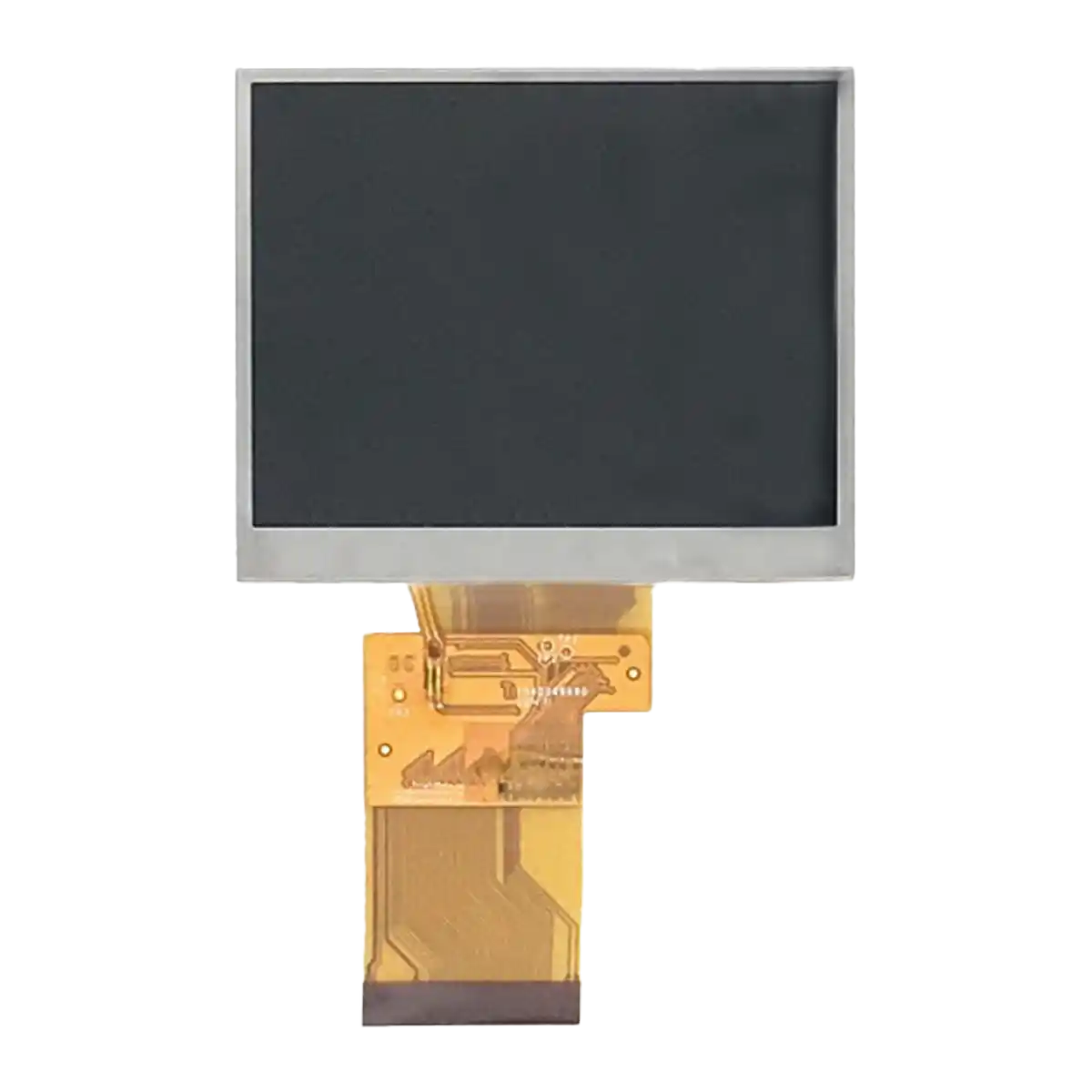

The BOE10.4-inch LCD BA104S01-300 provides a good display effect with its 800 × 600 resolution, 350cd/m² brightness and 800:1 contrast ratio, which is very suitable for the needs of industrial automation equipment. The viewing angle of this screen is 80/80/65/75(typ.) To ensure that clear visual effects can be obtained from different angles. In addition, the operating temperature range of the BA104S01-300 LCD screen is -30 to 80 ° C, which can adapt to various industrial environments.

Why did CNC machine tools choose BOE's BA104S01-300?

The BA104S01-300 is a 10.4-inch a-Si TFT-LCD industrial LCD screen produced by BOE, with a variety of detailed parameters and application advantages. The following are the main parameters and the reasons why customers choose this screen:

Detailed parameters:

-

Display color: 16.2M(8bits).

-

Response time: 30ms (typical).

-

Viewing angle: 80/80/66/75 (Typ.)(cr≥ 10).

-

Screen size: 10.4 inches.

-

Resolution: 800 x 600 pixels.

-

Brightness: 350 nits.

-

Contrast ratio: 800:1.

-

Operating temperature range:-20 to 70 ° C.

-

Backlight life: 30000 hours.

-

Interface type: LVDS (1 ch, 6/8-bit), Terminal Connection, 20 pins.

-

Refresh rate: 60Hz.

Reasons why customers choose to BA104S01-300 this screen:

-

High resolution and color performance: The screen supports 800 × 600 SVGA resolution and 16.2m color, which can provide clear and rich image display effect.

-

Wide viewing angle and high contrast: Its 80-degree viewing angle and 800:1 contrast ratio ensure a good visual experience at different viewing angles.

-

Wide temperature working environment: suitable for various industrial environments, capable of stable operation in the temperature range of -20 to 70 ° C, meeting the requirements of industrial equipment for environmental adaptability.

-

Long-life backlight system: The backlight life reaches 30000 hours, reducing maintenance costs and replacement frequency.

-

Customized services: provide customized services such as touch screen, driver board, wire and metal shell to meet the special needs of customers.

Problems BA104S01-300 Solved:

Customers choose the BA104S01-300 screen mainly to solve the following problems:

-

Insufficient Image Display quality: With high resolution and rich colors, the problems of low resolution and poor color performance in the past are solved.

-

Viewing angle limitation: Through the improved viewing angle design, the problem of poor display effect of traditional screens at different angles is solved.

-

Poor environmental adaptability: Through the design of a wide temperature working environment, the reliability of the equipment under extreme temperature conditions is solved.

-

High maintenance costs: The long-life backlight system greatly reduces maintenance costs and replacement frequency during long-term use.

With its excellent display performance, stable operating environment and flexible customized services, BA104S01-300 has become the choice of many industrial customers, and effectively solved their problems in image display quality and equipment reliability.

Ending

LEEHON is committed to innovation and customer satisfaction, and we understand the importance of continuous improvement. We believe that through our expertise and high-quality solutions, we can bring real value to our customers and drive the industrial automation industry forward.