Industrial LCD Screen: A Technical Overview

Introduction

In the realm of display technology, Industrial LCD Screens, or Liquid Crystal Display screens, have emerged as a critical component in various sectors, including manufacturing, automation, medical equipment, and transportation. These screens serve as the visual interface between humans and machines, providing real-time data, control interfaces, and status monitoring. Industrial LCD Screens are designed to meet the stringent requirements of industrial environments, which often demand robustness, reliability, and the ability to operate under extreme conditions.

Body

1. Fundamentals of LCD Technology

The core of an Industrial LCD Screen lies in its Liquid Crystal Display technology. Liquid crystals are substances that flow like liquids but have the optical characteristics of crystals. They exhibit a property called anisotropy, which means they have different properties in different directions. In an LCD, these crystals are sandwiched between two layers of glass that have a series of electrodes, allowing for precise control over the orientation of the liquid crystals.

2. Operational Principles

The operational principle of an LCD involves the manipulation of light transmission through the liquid crystal layer. A voltage is applied across the liquid crystals, which changes their alignment and, consequently, affects the amount of light that passes through them. This is achieved through the use of polarizing filters on either side of the liquid crystal layer. When no voltage is applied, light passing through the first polarizer is blocked by the second, aligned polarizer, creating a dark state. When voltage is applied, the crystals align to allow light to pass through, creating a bright state.

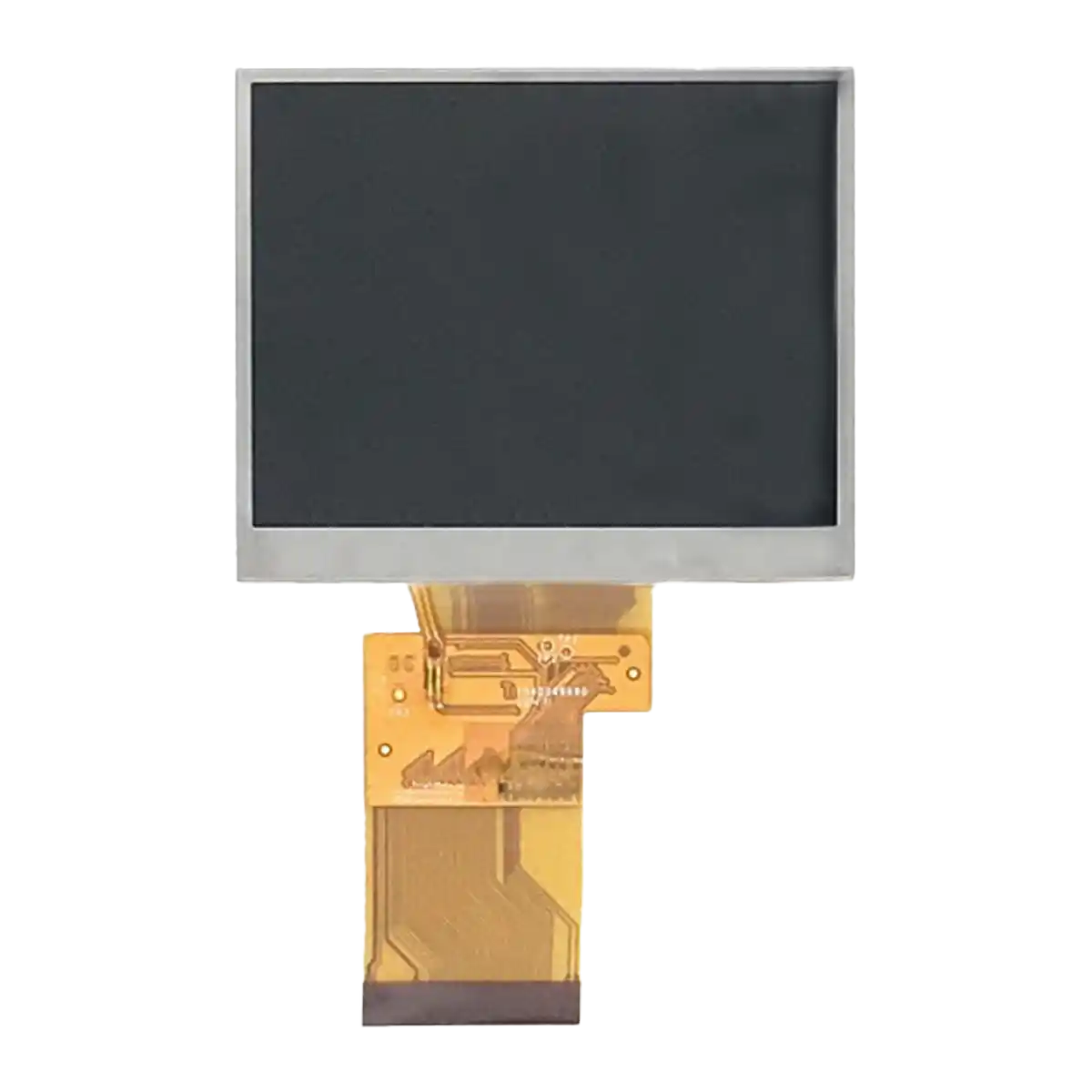

3. Types of Industrial LCD Screens

There are several types of Industrial LCD Screens, differentiated by their panel technologies, such as Twisted Nematic (TN), Super Twisted Nematic (STN), and Thin-Film Transistor (TFT). TN panels are known for their fast response times but limited viewing angles. STN panels offer better viewing angles but suffer from slower response times. TFT panels, on the other hand, provide high-quality images with better color reproduction and viewing angles, making them ideal for more demanding applications.

4. Key Characteristics

Industrial LCD Screens are characterized by several key attributes, including resolution, brightness, contrast ratio, response time, and viewing angle. Resolution refers to the number of pixels that can be displayed, with higher resolutions offering more detailed images. Brightness is measured in candelas per square meter (cd/m²) and is crucial for visibility in bright environments. The contrast ratio is the difference between the brightest white and the darkest black that the screen can display. Response time indicates how quickly pixels can change from one color to another, affecting motion clarity.

5. Environmental Considerations

Industrial LCD Screens are designed to withstand the rigors of industrial settings. They often feature wide temperature ranges, from -40°C to 85°C, ensuring operation in both freezing and scorching conditions. Vibration resistance and protection against electromagnetic interference are also critical for use in machinery and equipment that generate such disturbances.

6. Touchscreen Integration

Many Industrial LCD Screens incorporate touchscreen technology, allowing for direct interaction with the displayed interface. This can be resistive, where pressure is used to register touch, or capacitive, which detects the electrical conductance of the human body. Touchscreen integration enhances usability in control panels and interactive systems.

7. Backlighting

Backlighting is essential for the visibility of LCD Screens. Industrial LCD Screens typically use LED (Light Emitting Diode) backlighting, which is more energy-efficient and has a longer lifespan than traditional CCFL (Cold Cathode Fluorescent Lamp) backlighting. LED backlighting also allows for better control over brightness and uniformity.

Conclusion

Industrial LCD Screens are a testament to the evolution of display technology, offering high performance and reliability in challenging environments. Their ability to convey critical information and withstand harsh conditions makes them indispensable in modern industrial applications. As technology advances, we can expect further improvements in resolution, brightness, energy efficiency, and touch sensitivity, solidifying their role in the future of industrial automation and control systems.

Expansion

Looking ahead, the future of Industrial LCD Screens is promising. Developments in flexible and curved displays, as well as integration with smart sensors and IoT (Internet of Things) technologies, will open up new possibilities for industrial applications. Additionally, the push for energy efficiency and sustainability will drive innovations in power management and eco-friendly materials. As industrial processes become more automated and interconnected, the role of Industrial LCD Screens as the visual link in this ecosystem will only grow in importance.

Recommended Articles

-

Why Choose BOE’s EV101WXM-N10?

2025-01-03 -

The Trajectory of South Korea's LCD Industry Amidst Political Fluctuations and Technological Transition: Challenges and Opportunities Coexist

2025-01-03 -

ADS Pro: The Future of Display Technology

2025-01-03 -

Interpretation Report on AUO's New Generation Smart Cockpit

2025-01-03 -

What is the difference between quantum chips and quantum dot technology?

2025-01-03 -

Are the displays in Tesla's Cybertruck and Robovan the same as you imagined?

2025-01-03 -

BOE GV070WSM-N10 parameters and advantages and disadvantages analysis

2025-01-03 -

TM070RDH10-43 7-inch TFT-LCD Display: Technical Details and Application Guide

2025-01-03 -

Notice on the discontinuation of TCG104SVLQJPNN-AN41 model and alternative solutions

2025-01-03 -

Introduction: Reasons to Choose G121EAN01.2

2025-01-03 -

Practical Applications of Industrial LCD Screens: The Perfect Blend of Professionalism and Customization

2024-09-26 -

Hangzhou LEEHON Technology supplies BOE GT080X0M-N12: High quality 7-inch TFT-LCD module solution

2024-09-14 -

How to Check for Issues in Industrial LCD Panels

2024-09-11 -

How does an LCD screen find individual pixels?

2024-09-11 -

What is the difference between eDP and LVDS?

2024-09-11 -

In-depth analysis of the development of automotive display technology

2024-09-10