Industrial LCD Panels: A Deep Dive

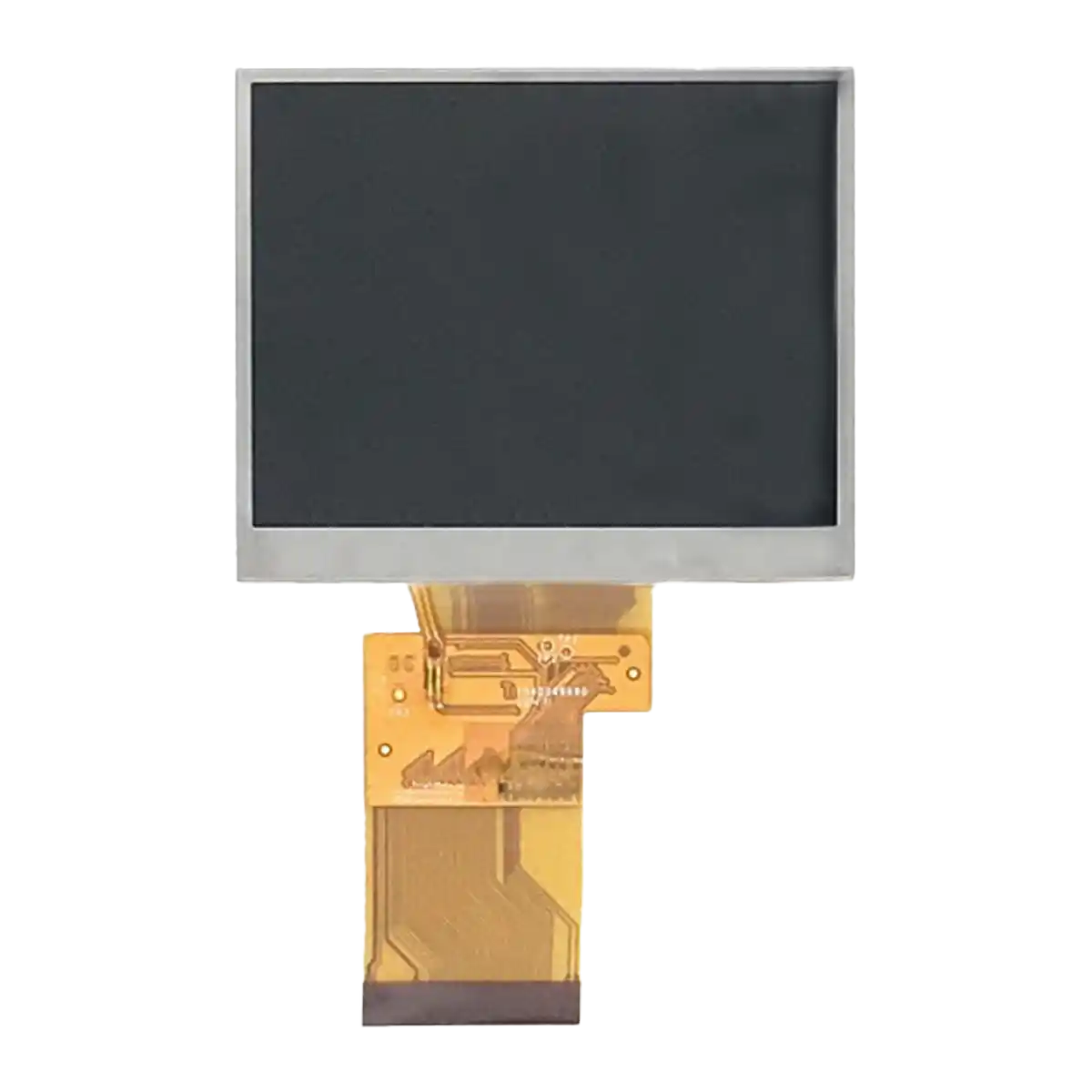

The term "Industrial LCD Panels" refers to a class of liquid crystal displays (LCDs) that are engineered to meet the stringent requirements of industrial applications. Unlike standard LCDs, these panels are built to operate in extreme temperatures, resist vibrations, and endure long periods of continuous use without degradation in performance.

1. Display Technology

At the heart of an Industrial LCD Panel lies the liquid crystal display technology. LCDs function by utilizing the properties of liquid crystals, which are molecules that possess both the fluidity of a liquid and the ordered structure of a crystal. These crystals respond to electric fields, changing their orientation and thereby affecting the amount of light that passes through them. This process is known as polarization, and it is manipulated through a series of electrodes and color filters to create the images we see on the screen.

2. Durability and Reliability

Industrial LCD Panels are distinguished by their robustness. They are encased in rugged housings that protect the delicate components from physical impacts and environmental factors such as moisture and dust. The use of high-brightness LEDs as backlights ensures that the display remains visible even in bright ambient light conditions, which is crucial for outdoor or well-lit industrial settings.

3. Touchscreen Integration

Many Industrial LCD Panels feature touchscreen capabilities, which are essential for interactive applications. Resistive, capacitive, and projected capacitive are common types of touchscreen technologies used in industrial settings. Resistive touchscreens are favored for their durability and ability to be used with gloved hands, while projected capacitive offers multi-touch capabilities and higher precision.

4. Environmental Sealing

To further ensure the longevity of Industrial LCD Panels, they are often sealed to prevent the ingress of contaminants. The Ingress Protection (IP) rating system is used to denote the level of sealing, with higher ratings indicating greater protection against dust and water.

5. Customizability

One of the hallmarks of Industrial LCD Panels is their customizability. Manufacturers can tailor the panels to meet specific client requirements, such as size, resolution, viewing angle, and temperature range. This adaptability makes them suitable for a wide array of applications, from control panels in factories to diagnostic screens in medical equipment.

Conclusion

In conclusion, Industrial LCD Panels represent a pinnacle of display technology, offering a blend of durability, clarity, and customization that is essential for the demanding environments they inhabit. Their ability to provide clear visuals and withstand harsh conditions without compromising performance makes them indispensable in the industrial sector.

Expansion

For those seeking to delve deeper into the world of Industrial LCD Panels, several areas of expansion present themselves. One could explore the various manufacturing processes involved in creating these panels, from the production of liquid crystals to the assembly of the final product. Additionally, the role of software in optimizing the performance of these displays and the integration with other industrial systems is a fascinating subject. Furthermore, the future of display technology, including the potential of OLEDs (Organic Light Emitting Diodes) and flexible displays, could be examined to understand how Industrial LCD Panels may evolve in response to these advancements.

In writing this article, I have aimed to provide a comprehensive overview of Industrial LCD Panels, ensuring that every technical term is explained in detail to cater to readers who may not be familiar with the subject matter. The depth and breadth of this exploration are intended to satisfy the curiosity of both novices and experts alike, shedding light on the critical role these panels play in the modern industrial landscape.

Recommended Articles

-

Why Choose BOE’s EV101WXM-N10?

2025-01-03 -

The Trajectory of South Korea's LCD Industry Amidst Political Fluctuations and Technological Transition: Challenges and Opportunities Coexist

2025-01-03 -

ADS Pro: The Future of Display Technology

2025-01-03 -

Interpretation Report on AUO's New Generation Smart Cockpit

2025-01-03 -

What is the difference between quantum chips and quantum dot technology?

2025-01-03 -

Are the displays in Tesla's Cybertruck and Robovan the same as you imagined?

2025-01-03 -

BOE GV070WSM-N10 parameters and advantages and disadvantages analysis

2025-01-03 -

TM070RDH10-43 7-inch TFT-LCD Display: Technical Details and Application Guide

2025-01-03 -

Notice on the discontinuation of TCG104SVLQJPNN-AN41 model and alternative solutions

2025-01-03 -

Introduction: Reasons to Choose G121EAN01.2

2025-01-03 -

Practical Applications of Industrial LCD Screens: The Perfect Blend of Professionalism and Customization

2024-09-26 -

Hangzhou LEEHON Technology supplies BOE GT080X0M-N12: High quality 7-inch TFT-LCD module solution

2024-09-14 -

How to Check for Issues in Industrial LCD Panels

2024-09-11 -

How does an LCD screen find individual pixels?

2024-09-11 -

What is the difference between eDP and LVDS?

2024-09-11 -

In-depth analysis of the development of automotive display technology

2024-09-10