Industrial LCD screens are the core of durable display solutions

Introduction

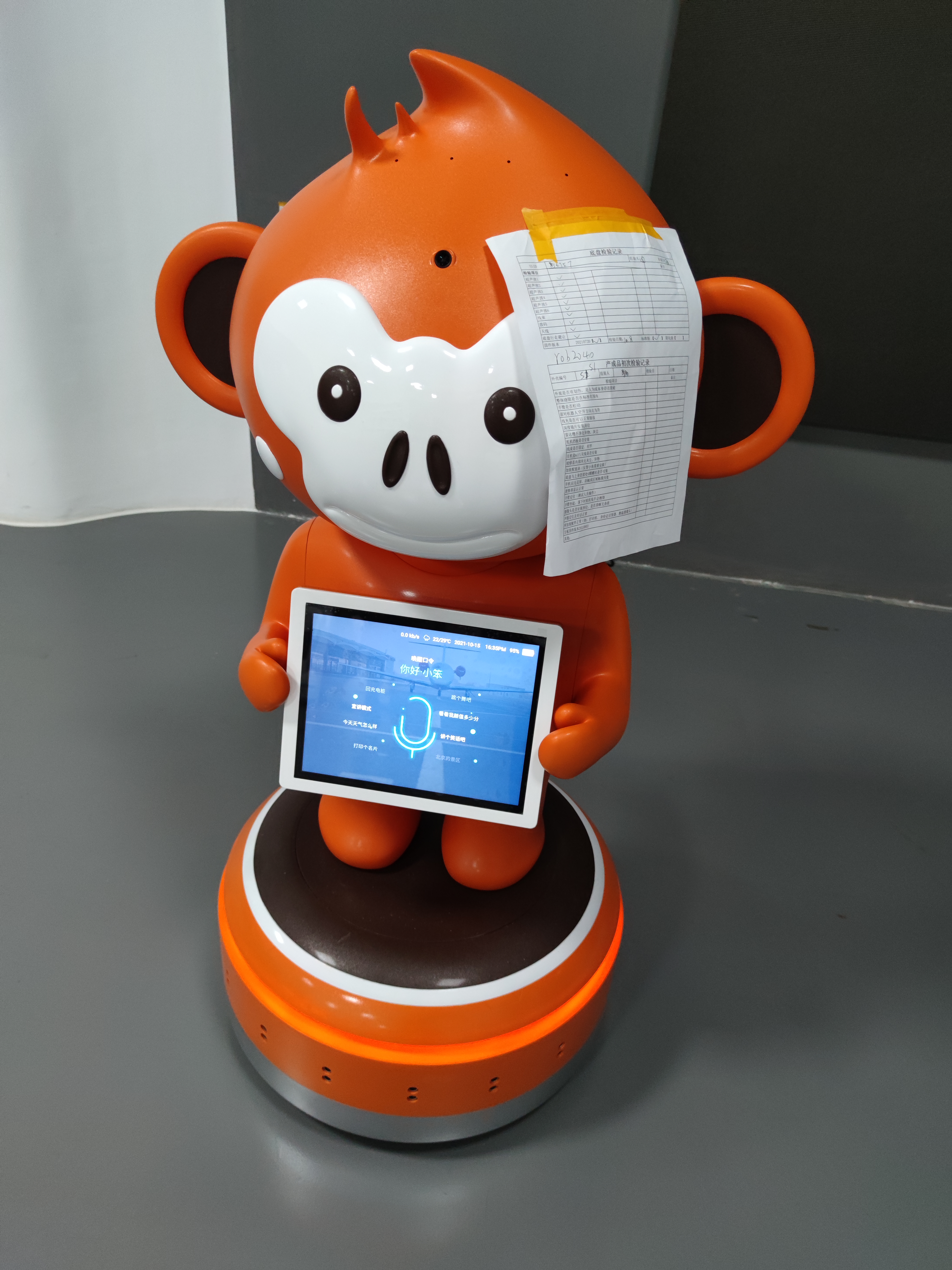

In the dynamic landscape of industrial automation and control systems, the role of display technology is paramount. Industrial LCD screens, or Liquid Crystal Display (LCD) screens designed for industrial use, have become the cornerstone of reliable and robust display solutions. These screens are not just a means of visual representation; they are critical components that ensure the smooth operation of machinery, the accuracy of data presentation, and the efficiency of industrial processes. The term "Industrial LCD Screens" refers to a category of displays that are specifically engineered to operate in environments that are often harsh, dusty, hot, or cold, and where downtime can be costly.

The Essence of Industrial LCD Screens

At the heart of an Industrial LCD Screen is the Liquid Crystal Display technology. LCDs function by utilizing the properties of liquid crystals, which are organic compounds that flow like liquids but maintain the structural characteristics of solid crystals. These crystals can be manipulated to control the passage of light through an electric field, which is how images and information are displayed.

1. Polarizers: These are filters that allow light to pass through only in specific orientations, playing a crucial role in the LCD's ability to control light.

2. Electrodes: Transparent conductive layers that apply an electric field across the liquid crystals.

3. Color Filters: Used in color LCDs to produce the full spectrum of colors by filtering white light.

4. Backlight: A source of light that照亮the LCD from behind, making the display visible.

Industrial LCD screens are distinguished by several key features that set them apart from their consumer counterparts:

- Ruggedness: They are built to withstand physical impacts and environmental stresses such as temperature fluctuations, humidity, and vibrations.

- Brightness: High brightness levels ensure that the display is visible even in bright ambient light conditions.

- Wide Temperature Range: Industrial LCDs can operate effectively in a broad range of temperatures, which is essential for outdoor or temperature-controlled environments.

- Long Lifespan: They are designed for extended use, often with a lifespan of over 50,000 hours, which is crucial for 24/7 operational environments.

Applications and Benefits

Industrial LCD screens are integral to a wide array of applications across various industries. In manufacturing, they serve as human-machine interfaces (HMIs) for controlling assembly lines and monitoring production metrics. In transportation, they are used in vehicle dashboards and navigation systems, providing critical information to drivers. In medical equipment, they display vital signs and diagnostic data, aiding in patient care.

The benefits of using Industrial LCD screens include:

- Enhanced Visibility: High contrast ratios and brightness ensure that information is clear and readable.

- Reliability: Durability against environmental factors reduces the risk of failure and increases uptime.

- Customizability: Industrial LCDs can be tailored to specific needs, such as size, resolution, and touch capabilities.

- Energy Efficiency: Many industrial LCDs are designed with energy-saving features, which is beneficial for long-term operational costs.

Conclusion

Industrial LCD screens have established themselves as the backbone of robust display solutions in the industrial sector. Their ability to provide clear, reliable, and durable displays in challenging environments is unmatched. As technology continues to evolve, we can expect further advancements that will enhance their capabilities, making them even more integral to the future of industrial automation and control.

Recommended Articles

-

Hangzhou LEEHON Technology supplies BOE GT080X0M-N12: High quality 7-inch TFT-LCD module solution

2024-09-14 -

How to Check for Issues in Industrial LCD Panels

2024-09-11 -

How does an LCD screen find individual pixels?

2024-09-11 -

What is the difference between eDP and LVDS?

2024-09-11 -

In-depth analysis of the development of automotive display technology

2024-09-10